Because LED has the advantages of high brightness, power saving and long life, it has been widely used in traffic signal lights. According to statistics, there are about 20 million traffic lights in the world. In 2000, there were about 400,000 traffic lights in Pingtian LED around the world. In 2001, it reached 1 million, and the growth rate reached 150%. It is estimated that 2 million new LED traffic lights are added globally every year. Based on an update cost of about US$500 per seat, there will be a US$1 billion market for LED consumption in urban LED traffic lights in the world every year in the future.

At night, high-luminosity LED urban traffic lights have also begun to be applied. Traffic signals use LED light-emitting diode light sources. Each intersection requires 12 yellow and green signal lights, plus 24 pedestrian crossing warning lights (8 sets), a total of 36, of which 12 are blue-green signal lights, so each intersection needs 2400 Only blue and green LEDs are highlighted. In 2000, there were 663 cities in China, including 37 megacities, 51 large cities, 216 Zhongbo cities, and 359 small cities. With an average of 500 intersections in each city, the national Tongai needs about 800 million high-brightness blue-green LEDs.

With the expansion of cities and the acceleration of urbanization, municipal construction facilities are also a large space. Small cities and even towns need equipment, including highway entrances and exits, and traffic lights at intersections of superhighways. It is estimated that this is a market of more than 1.5 billion yuan. With the continuous improvement of energy saving, environmental protection and traffic safety requirements, and the continuous decline of LED prices, more and more LEDs will be used to replace old lights and traffic lights. .

Device design of LED traffic lights

Using LED traffic lights to replace traditional incandescent lamps can save more than 80% of electricity, and its optical performance is better than that of 100W incandescent lamps. In order to ensure that the service life of traffic lights can exceed 5 years, it is suggested that the following technical measures should be taken when designing LED traffic lights.

In the signal lamp, through-hole LEDs are selected, and LED chips with higher brightness are used. It is best to use copper brackets for the selected LEDs. When designing the printed circuit board, the area of the copper clad laminate should be larger, which is conducive to the heat dissipation of the LED (the heat is dissipated by the copper strip of the circuit board).

When selecting LED, its design index should be 20% brighter than that required by traffic signal lights. Using reflective cup technology can improve the light output effect of signal lights.

The driving current should adopt a reliable constant current power supply. When the voltage changes within the range of ± 20%, the current change is controlled within ± 1 mA. Because the forward voltage of the LED decreases with the rise of temperature, if the resistance step-down, capacitive step-down or constant voltage method is used, the current will increase accordingly, which will cause the temperature to rise, resulting in a vicious cycle until the LED is damaged.

There should be room for the current that each LED bears, which is less than the current value of 20mA usually used at room temperature. For example, the red and yellow LEDs use 17~18 mA, and the blue and green LEDs use about mA. From the limit operating current of the LED and the ambient temperature It can be seen from the relationship that for the red and yellow LEDs, when the temperature rises to 80C, the limit current is only 23, and when the temperature rises to 70C, the limit current is only 10 mA, which exceeds the limit allowable current of these two LEDs. The LED is about to break.

Technical standards for LED traffic lights

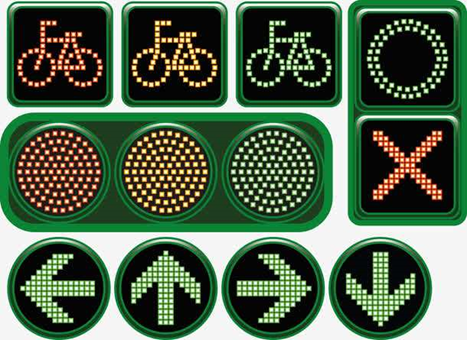

So far, LED traffic lights have circular red, green, and yellow lights, arrow-shaped green lights, and red, yellow, and green lights for sidewalks. The technical standards of these types of lamps are different, but their light intensity and luminance values are all measured at the viewing angle in the horizontal direction. On the horizontal light ground, there are 5” on both sides of the horizontal angle, 10° on both sides of the horizontal angle, 15” on both sides of the horizontal angle, 20” on both sides of the horizontal angle. 5°, depression angle of 10″, and depression angle of 20* to measure the optical indicators of famous points. As for the color of signal lights, the standards of different countries are also different.

Due to the harsh environmental conditions of traffic lights, high and low temperature tests should be carried out in cycles of -40~60C. The requirements for the waterproof conditions of the traffic signal lights are also relatively high. Under a certain water pressure, the traffic signal lights can be impacted from all sides, and it is necessary to ensure that no water can enter. Dustproof is also another requirement for traffic lights, that is, the surface lens should not be stuck with dust. For the above standards, you can check the specific test indicators of the traffic department. There is a research institute in the traffic department that is responsible for the testing and inspection of traffic signal indicators.

At present, the LEDs used in traffic lights are different. There are 0.5 mm red, green and yellow single-tube combinations. Because the luminous flux emitted by a single LED is small, 100-300 LEDs are usually used to distribute them evenly on the entire light-emitting surface. superior. With the improvement of the light output efficiency of a single LED, it is also possible to use only Shierdun LEDs to form a signal light.

For LEDs used as traffic lights, it should be designed according to relevant technical indicators and basic parameters such as voltage, current, and luminous flux of a single LEDE. Now there are many technical materials for designing traffic lights, which can be consulted by relevant professional and technical personnel.