Packaging process of diodes

Diode (LED) is a semiconductor device widely used in fields such as lighting, display, indication, and communication. The performance and wide application of LED depend on its packaging method. In this article, we will explore the importance of diode packaging and the characteristics and applications of different packaging types.

The importance of diode packaging

Packaging is the process of protecting LED chips inside the casing, which has the following important functions:

1. Protection chip: LED chips are extremely fragile and susceptible to environmental factors and mechanical damage. Packaging can provide protection and extend the lifespan of LEDs.

2. Heat dissipation: LEDs generate heat during operation, and high temperatures can affect their performance and lifespan. Packaging usually includes a heat dissipation structure, which helps to effectively dissipate heat and ensure the stable operation of LEDs.

3. Optical effect: Different packaging methods can affect the optical performance of LEDs, including light intensity, angle distribution, and color temperature. Proper packaging can optimize these optical parameters to meet specific application requirements.

Different diode packaging types

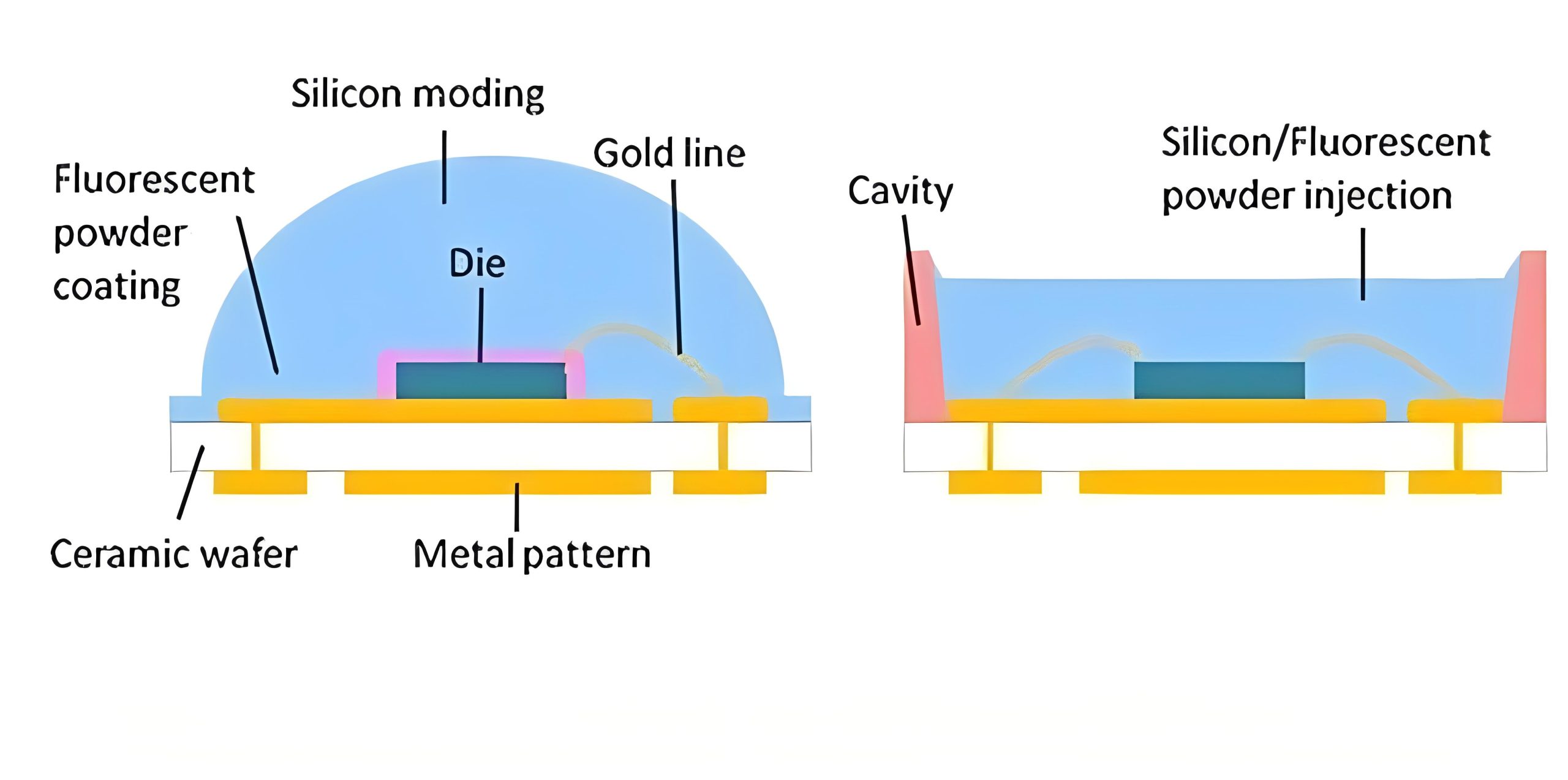

Surface Mount Packaging (SMD): SMD LED packaging is a widely used packaging method for electronic products. It has the characteristics of being compact, lightweight, and easy to solder, suitable for applications such as LED screens, displays, and lighting.

1. Guided packaging: Guided packaging is a method of encapsulating LED chips in a transparent guide body. It can improve optical performance, provide uniform light scattering, and is suitable for lighting and display applications.

2. High power packaging: High power LED packaging is usually larger and can handle higher currents and power. They are widely used in high brightness applications such as outdoor lighting, automotive lighting, and plant growth lighting.

3. COB packaging: COB (Chip on Board) packaging densely integrates multiple LED chips onto the same substrate, providing high brightness and uniform lighting effects. It is suitable for high-power lighting and projection applications.

4. Multicolor packaging: Multicolor LED packaging integrates LED chips of different colors, which can be used for RGB lighting, display, and color effect creation.

5. UV and infrared packaging: UV and infrared LED packaging is commonly used for special applications such as UV curing, infrared sensing, and safety monitoring.

In short, diode packaging is an indispensable part of LED technology, which affects the performance and application of LEDs. Different packaging methods are suitable for different application needs, and future development trends will continue to drive innovation and progress in LED packaging technology. LED packaging will continue to play an important role in lighting, display, communication, and other fields.